- Call us: 0129-2980757

- Email: sales@limitorqueindia.com

Quarter turn Gear Box

(A) Quarter turn worm gear operators Type ‘T’

The “T” series operators have been designed for any valve or mechanism which requires 90°rotation. Uses are : butterfly, plug and ball valves, louver dampers, flap gates or any device (mechanism) requiring 90° movement.

These operators have been used successfully throughout industries in all sectors such as water and waste treatment works, power plants, petrochemical facilities, marine service, chemical processing and power transmission areas.

All standard units are built for outdoor service are weatherproof and are factory lubricated.

| TYPE | Sr.No. | MODEL | TORQUE CAPACITY (MKG) | |

| MOTORISED | MANUAL | |||

| Quarter turn worm gear

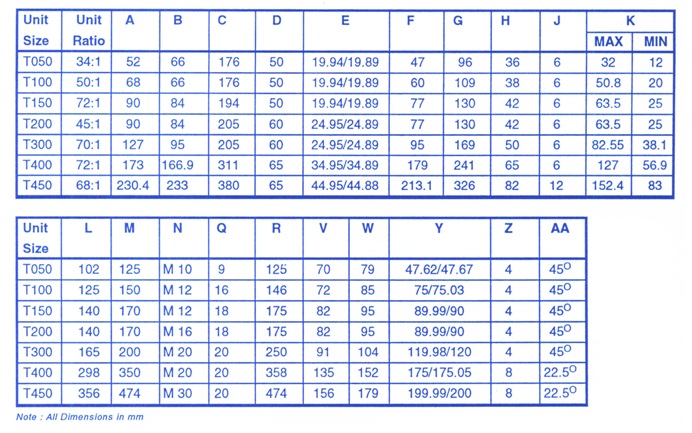

operators Type ‘T’ QUARTER-TURN GEARBOX WITH SPURGEAR ATTACHMENT Data

|

01 | 1.1.1 T050 | 61 | 83 |

| 02 | T100 | 102 | 138 | |

| 03 | T150 | 152 | 207 | |

| 04 | T200 | 248 | 303 | |

| 05 | T300 | 373 | 455 | |

| 06 | T400 | 1214 | 1863 | |

| 07 | T450 | 2898 | 4416 | |

- Technical Data

Each units sizes are furnished with mechanical stops which are externally adjustable for 90° of travel with plus or minus 5° adjust-ability. All units are supplied with mechanical position indicators for visual determination of valve position. The output of the units can be directly bored and keyed to specific shaft requirements or can be supplied with splined adaptors to permit customer machining.

Input torque valve can be determined by dividing output torque values by (ratio x efficiency).

(B) HBC Worm Gear Type

The hand operated type HBC unit is a worm gear drive which may be used for any valve or device requiring 90 Degree as well as 360 Degree (Guillotine Dampers and Rack and pinion) movement.

This actuator is used as the manual operator attached with a hand wheel. It also can be remotely controlled combined with motorized Limitorque Valve controls. HBC unit is furnished with spur gear and bevel gear attachments to reduce manual operating force. The worm is of alloy steel and furnished with tooth grinding, and the worm gear is of high tensile strength bronze; therefore the HBC unit is very compact and strong. Fluttering of valve has been minimized because of least backlash of high precision gears.

HBC units are provided with double sleeve, relation with the key way position of valve/ damper shaft can be taken freely.

| HBC SERIES | ||||||||||||

| TYPE & SIZE | H0BC | H1BC | H2BC | H3BC | H4BC | H5BC | H5(1/2)BC | H6BC | H7BC | H8BC | H10BC | |

| GEAR RATIO | 71:1 | 70:1 | 70:1 | 70:1 | 60:1 | 65:1 | 67:1 | 66:1 | 69:1 | 64:1 | 61:1 | |

| MAX. TORQUE NM (KGM) | E | 600 (61) | 1775 (181) | 3000 (306) | 7650 (780) | 17325 (1766) | 26500 (2700) | 40000 (4077) | 62300 (6350) | 85950 (8761) | 132450 (13500) | 196200 (20000) |

| M | 900 (92) | 2660 (271) | 4500 (459) | 11475 (1170) | 25988 (2649) | 39750 (4050) | 60000 (6116) | 93450 (9525) | 128925 (13142) | 198675 (20252) | 294300 (30000) |